While calculating loads arise from stored grains in bins, existing theories assume that the pressure distribution around the bin perimeter is uniform at any given depth. But in practical, there is always a chance of non-uniformity of loading. The possible reasons for this may be non-concentric filling techniques, imperfections in bin walls or grain discharge outlets may located eccentrically.

Also, pressure exerted by grain on bin wall is different for stationary and flowing condition. When the stored grains allow to flow through discharge outlet, bin walls are experienced high localized pressures of short duration.

According to research studies, there are two types of high pressure during discharge. One is the kick load (which occurs at the start of flow and is only significant in hopper) while second high pressure is characterized by local stress re-distribution within flowing grain mass as it passes the imperfections of the bin walls.

While designing bin, neglecting the non-uniform loading results in bin failure. Pressures due to eccentric discharge outlets may be higher or lower than the predicted uniform pressure.

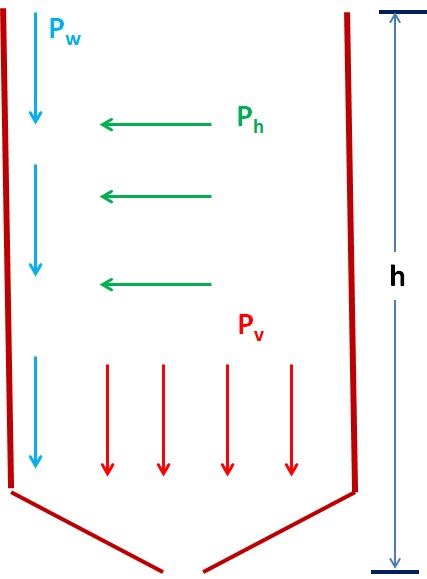

Stored grains in bins exert three types of loads. 1) Horizontal pressure (Ph) acting on the side walls 2) Vertical pressure (Pv) acting on the cross-sectional area of bin filling 3) Frictional wall pressure (Pw)

For detailed reading, visit the ICAR e course by clicking below link http://ecoursesonline.iasri.res.in/mod/page/view.php?id=918