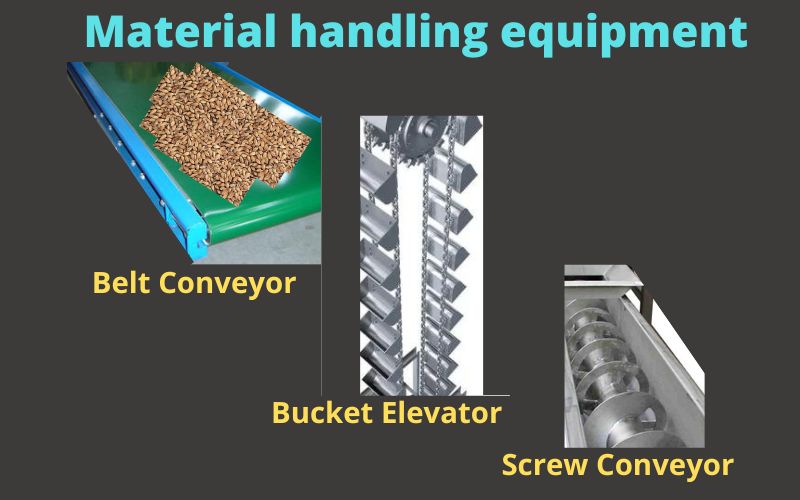

Material handling equipment

In grain processing, material i.e. grains are conveyed from one processing machine to another for various post harvest operations. For this purpose, many mechanical devices are used to reduce the human drudgery. These equipment are known as material handling equipment.

Material handling equipment are the equipment used for the movement of materials during the manufacturing process of any products. These can also be used for transportation of materials from one place to another in a processing plant.

Though there are several material handling equipment are used in different industry for different purpose, this post explains use of 1) Belt Conveyor 2) Bucket Elevator and 3) Screw Conveyor in Agricultural and food processing.

Material handling equipment

Belt conveyor

Belt conveyor is an endless belt running between two pulleys and driven by prime mover. The belt is supported by flat or troughed idlers provided at intermediate points. The material to be conveyed is loaded at starting point and unloaded at the end. However, loading and unloading of material can be done at intermediate points also.

The parts of belt conveyor are:

- The belt

- Drive and driven pulleys

- Belt tension adjustment mechanism

- Idlers (Straight/Troughed)

- Loading and unloading devices.

The belt must be flexible enough to take the shape of the pulleys and idlers, yet strong enough to deliver the desired capacity.

Bucket Elevator

Bucket elevator is used for conveying grains in vertical direction. Bucket elevator has an endless belt fixed with buckets to lift the grains. The bucket may be made of metal or plastic.

The belt moves on two pulleys and load the grains at ground level which is then discharged at specific height for input to cleaning/grading or other machine. The height of lift may be up to few meters.

Bucket carries grains while travelling vertically and discharged this grain mass by inverting the buckets at head (top) pulley. The empty buckets again come back for filling the grains at bottom. At the bottom inclined or hopper like portion may provided for easy filling of grains.

Screw Conveyor

Screw conveyors are used for conveying grains in horizontal as well as in inclined direction limited up to certain angle. These are operated in a U shaped trough, with or without any cover, depending upon direction of movement and characteristics of material to be conveyed.

The screw shaft is connected to shaft of electric motor by flexible coupling. At one end of screw conveyor material is received and at the other end it is discharged. Capacity of screw conveyor is depends on screw diameter, conveying velocity and loading efficiency.

The rotation of screw flight pushes grains in forward direction similar to principle of nut and bolt movement. The advantage of screw conveyor is that it require very less space and can arrange in congested spaces also. Treatment of seeds can also done in screw conveyor.